Caster Buying Guide: Find the Perfect Fit

- Introduction

- Assess Load Capacity

- Evaluate Environmental Conditions

- Consider Flooring Type

- Determine Mobility Requirements

- Select Appropriate Wheel Material

- Choose the Right Caster Type

- Factor in Ergonomics

- Prioritize Maintenance and Durability

Introduction

Casters ensure safe and efficient movement in settings ranging from factories and laboratories to offices and hospitals. The right choice can significantly impact how easily and safely heavy objects are transported, reducing the risk of injury and damage. Whether upgrading industrial equipment or furnishing a workspace, selecting high-quality solutions like Blickle casters ensures your equipment rolls smoothly, quietly, and reliably.

With so many options on the market, it’s essential to understand the core criteria for choosing the correct caster. This detailed guide provides a step-by-step approach to help you determine which type of caster best fits your unique application, ensuring optimal mobility, durability, and safety for your operation.

Assess Load Capacity

Begin your caster selection process by determining the total weight your casters must support. This should include not only the weight of the transported item itself but also any contents or accessories. To ensure optimal performance, divide the total load by the number of casters and subtract one. This calculation provides a safety buffer for uneven surfaces that could overload a single caster. For example, equipment weighing 2,000 lbs with four casters should be rated for at least 667 lbs. Adhering to proper load capacity is vital for both safety and caster longevity. For a detailed explanation, consult Rockler’s guide to choosing the right casters.

Evaluate Environmental Conditions

Environmental factors greatly influence caster performance. Environments exposed to harsh chemicals, water, or extreme temperatures require special attention to materials and design. Stainless steel or zinc-plated casters are ideal for humid or wet settings, while high-heat applications need casters made from heat-resistant polymers or metals. Consider the frequency of cleaning and whether the casters will be subjected to oils, acids, or abrasive debris commonly found in certain industrial environments.

Consider Flooring Type

The surface on which your casters will roll is as vital as the environment. Hard floors, like tile, concrete, or hardwood, benefit from softer wheels made of rubber or polyurethane to minimize noise and floor damage. Conversely, thicker carpet or soft, uneven surfaces may require hard wheels or larger diameters to avoid excessive rolling resistance and prevent getting stuck. Ensuring wheel material and floor surface compatibility increases mobility and prolongs the life of equipment and flooring.

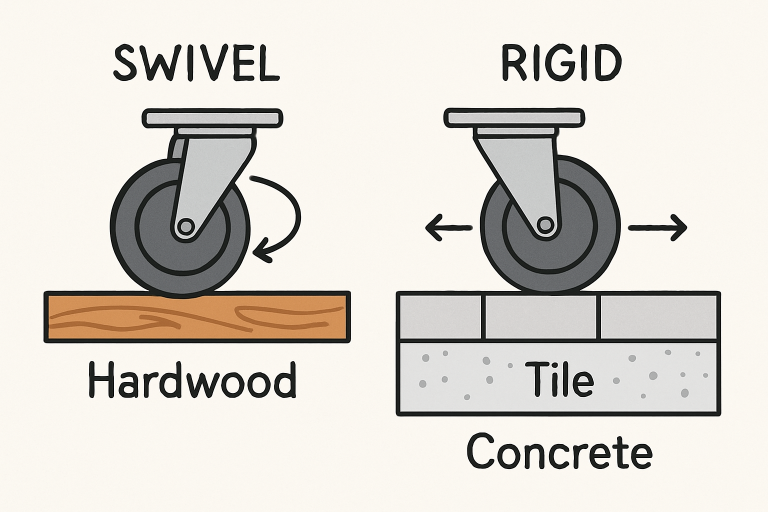

Determine Mobility Requirements

The mobility pattern required for your application dictates whether you should choose swivel, rigid, or a combination of both caster types. Swivel casters provide excellent maneuverability and are best suited for tight spaces and frequent directional changes. Rigid casters keep movement linear and are efficient for transport along straight paths. Combining the two types can achieve the ideal balance of control and flexibility for equipment that frequently transitions between long runs and precise positioning, such as hospital beds or warehouse carts.

If you want an in-depth look at design innovations and practical applications, check out this comprehensive resource from WOOD Magazine.

Select Appropriate Wheel Material

Wheel material affects the caster’s performance, longevity, and impact on the floor. The most common options include:

- Rubber: Ideal for protecting floors and reducing vibration and noise. Best for light to moderate loads and sensitive environments.

- Polyurethane: Offers an excellent balance between hardness and flexibility, suitable for a wide range of floors and loads while resisting chemicals and abrasion.

- Metal is perfect for heavy loads in industrial settings, but can be noisy and damaging to delicate floors without protective coatings. It is often used in factories, warehouses, and high-temperature environments.

Choose the Right Caster Type

Casters are engineered for various applications. Light-duty casters suit office chairs and carts, while heavy-duty industrial casters can support loads of 30,000 pounds or more. Specialized types such as pneumatic casters provide shock absorption for outdoor and rough terrain use, while low-profile casters enhance stability in compact applications. Selecting the right style ensures safety and efficiency, so always match the caster type to your application’s demands. For further insights, the Wikipedia entry on caster technology offers a deep dive into caster mechanics and history.

Factor in Ergonomics

Well-designed casters can significantly improve workplace ergonomics by reducing the force required to start and sustain movement. Ergonomically optimized casters feature larger wheel diameters, precision bearings, and low-resistance designs, which decrease manual effort and reduce the risk of workplace injuries. This is particularly important in environments where equipment is frequently moved by hand, such as hospitals or assembly lines.

Prioritize Maintenance and Durability

Choose casters that allow easy cleaning, lubrication, and replacement of worn components. Investing in high-quality, maintainable casters can drastically reduce equipment downtime and replacement costs over the product’s lifetime. Regular inspections for wheel wear, fork deformation, and faulty bearings help keep casters reliable and extend their usable life. Premium casters may have a higher upfront price, but the long-term savings and improved safety make them a smart investment.

By thoroughly considering these elements—load capacity, environment, flooring, mobility, material, type, ergonomics, and maintenance—you’ll select casters that not only fit your unique requirements but also maximize efficiency, safety, and operational longevity.