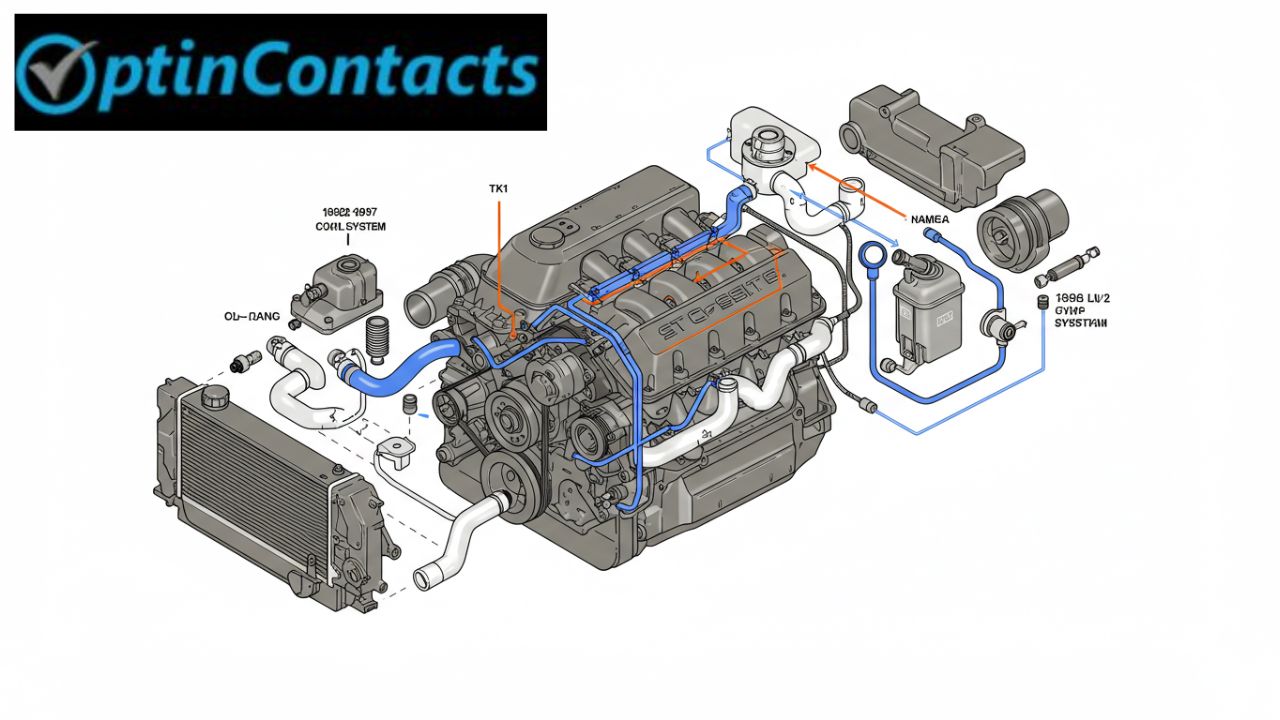

Complete Guide to the 192-97 LT1 Cooling System: How It Works and Why It Matters

When it comes to maintaining peak engine performance,it is one of the most critical elements to understand. Specifically designed for GM’s powerful LT1 engines from the early to mid-90s, this cooling system broke the mold of conventional engine cooling. Unlike traditional cooling systems, the LT1 version uses reverse flow technology, ensuring optimal temperature control even in high-performance driving conditions.

What Is the 192-97 LT1 Cooling System?

it’s refers to a specially engineered thermal management system used in LT1 engines manufactured between 1992 and 1997. These engines appeared in iconic models like the Chevrolet Corvette, Camaro Z28, and Pontiac Firebird Trans Am. Unlike typical engine cooling systems that circulate coolant from the block to the cylinder heads, the LT1 system was designed to cool the heads first, resulting in improved performance and efficiency.

This innovative design is part of what allowed these cars to push higher horsepower limits while maintaining reliability on the street and track.

Key Features of the 192-97 LT1 Cooling System

Understanding what sets the 192-97 LT1 cooling system apart is important for both enthusiasts and mechanics. Its standout features include:

1. Reverse Coolant Flow

Coolant moves from the radiator into the cylinder heads before reaching the engine block. This keeps the combustion chambers cooler, allowing the engine to run higher compression ratios without knocking.

2. High-Capacity Water Pump

The system uses a reverse-flow water pump built specifically to match the unique circulation path. This pump ensures coolant is evenly distributed throughout the heads and block.

3. Low-Temperature Thermostat

Many LT1 engines use thermostats rated between 160°F to 180°F. This allows the engine to run cooler, improving throttle response and combustion efficiency.

4. Integrated Cooling Fans

Electric fans in the LT1 setup are controlled electronically and engage based on coolant temperature, providing responsive and consistent engine cooling under all conditions.

How the 192-97 LT1 Cooling System Operates

The flow dynamics of the 192-97 LT1 cooling system differ significantly from older engine designs. Here’s a breakdown of its operating cycle:

Coolant exits the radiator and enters the water pump.

From there, it flows directly to the cylinder heads, the hottest parts of the engine.

Once the heads are cooled, the coolant circulates down into the engine block.

After absorbing heat from the block, it returns to the radiator, where it is cooled again by airflow and fans.

This sequence prevents heat buildup at the top of the engine, where detonation and overheating are most likely to occur.

Benefits of the 192-97 LT1 Cooling System

The unique layout of it offers several performance and durability advantages:

Enhanced Engine Performance: Cooling the cylinder heads first allows the engine to operate at higher compression levels without knocking.

Improved Fuel Efficiency: Better combustion control results in less wasted fuel and reduced emissions.

Thermal Stability: The engine maintains more consistent operating temperatures, improving long-term durability.

Track-Ready Reliability: Whether on the street or the track, the system prevents overheating even under heavy loads.

Components of the 192-97 LT1 Cooling System

To fully appreciate the value of this system, it’s important to know the major components involved:

a) Water Pump

A reverse-flow water pump is essential in this setup. It’s responsible for delivering coolant in the non-traditional direction needed to prioritize head cooling.

b) Radiator

The aluminum radiator used in these vehicles has high cooling efficiency and supports the high-flow characteristics of the system.

c) Coolant Hoses

These specialized hoses are routed to support the reverse flow path, and they must be heat-resistant and correctly fitted to prevent leaks.

d) Thermostat and Sensors

The thermostat regulates coolant flow, while temperature sensors send signals to engage electric fans and monitor system health.

e) Heater Core

The heater core, while mainly for cabin heat, also plays a role in coolant circulation and can be an early indicator of system failure when clogged.

Common Problems in the 192-97 LT1 Cooling System

While the 192-97 LT1 cooling system is efficient, it’s not without its vulnerabilities. Here are the most common issues to watch out for:

Leaky Water Pump Seals

Since the water pump handles high flow and reverse direction, its seals can wear down over time, leading to coolant leaks.

Clogged Radiator Fins

Debris and corrosion can block airflow through the radiator, reducing its ability to cool the circulating fluid.

Air Pockets in the System

Due to the unique flow pattern, improper bleeding can trap air pockets, which leads to overheating and hot spots.

Faulty Thermostat

A stuck thermostat can either prevent the engine from warming up or cause it to overheat.

How to Maintain the 192-97 LT1 Cooling System

Keeping the 192-97 LT1 cooling system in good shape ensures the engine continues to run at optimal performance levels. Here are key maintenance tips:

Flush the System Regularly

Flush and replace the coolant every 24,000 to 36,000 miles to avoid corrosion, sediment buildup, and scale formation.

Use the Correct Coolant

Stick to GM-recommended coolant and never mix incompatible types, as it can damage internal components.

Inspec t Hoses and Clamps

Regularly check all hoses for cracks, swelling, or leaks. Replace them if they show signs of wear.

Check the Fan Operation

Make sure the electric fans engage properly when the engine reaches operating temperature. Faulty sensors or relays can delay activation.

Bleed the System Properly

Always bleed the system using the factory bleeder valves after replacing any components to remove air pockets.

Performance Upgrades for the LT1 Cooling System

Performance enthusiasts often upgrade the 192-97 LT1 cooling system to handle increased power output. Some popular upgrades include:

Aluminum Performance Radiators for better heat dissipation.

High-Flow Water Pumps to increase coolant circulation.

Electric Fan Kits with Adjustable Controllers to enhance cooling responsiveness.

Coolant Additives that improve heat transfer and prevent internal corrosion.

These upgrades not only enhance performance but also extend the life of engine components.

Final Thoughts

The 192-97 LT1 cooling system is a vital part of what made the LT1 engine platform so successful during the 1990s. Its advanced design, reverse coolant flow, and carefully engineered components allow it to maintain thermal efficiency under demanding conditions. Whether you’re maintaining an original vehicle or upgrading for performance, understanding and properly caring for this system will ensure reliable and powerful engine operation for years to come.